Study on the hydraulic performance of the axial flow main coolant pump for lead-cooled fast reactor

Abstract

Lead-cooled fast reactor (LFR) has been listed as the most promising fourth-generation reactor type for commercial applications. LFR uses liquid heavy metal, lead or lead–bismuth eutectic alloy (LBE) as the coolant. It has completely different physical parameters such as the density and viscosity from the traditional nuclear reactor coolant, water. Different physical parameters will have a noticeable effect on the hydraulic performance of the main coolant pump. In this study, based on SST k-w turbulence model, an axial flow main coolant pump in the LFR at multiple working conditions was simulated, and the differences of its hydraulic performance under LBE and water and the reasons were analyzed in detail. Both the head and efficiency of the axial flow pump model under LBE are higher obviously than that under water, and the theoretical head is basically the same under the two mediums. The increase of the head and efficiency under LBE mainly results from the decrease of profile losses in the impeller and guide vane, both the friction loss and losses due to vortices in the boundary layer and wake formation at the outlet of the blade are obviously smaller than that under water.

https://doi.org/10.1016/j.nucengdes.2023.112375

Keywords

Lead-cooled fast reactorHydraulic lossFriction shear stressTurbulent kinetic energyReynolds number

Abbreviations

LFRLead-cooled fast reactorLBElead or lead-bismuth eutectic alloyMCPmain coolant pumpLHMLiquid heavy metal

1. Introduction

Energy conservation and emission reduction have been a common goal of all countries in the world because of the increasingly prominent greenhouse effect. Climatologists pointed out that only if the global greenhouse gas emissions must be close to the peak before 2025 and reduced by 43% before 2050, can we possibly reach the goal of the Paris Climate Agreement of limiting temperature rise to less than 1.5 ℃ (IPCC, 2022). The world will need to harness all low-carbon sources of energy in order to meet the Paris Agreement goal. The use of renewables such as wind and solar power will continue to grow. However, nuclear power provides the steady and reliable stream of electricity needed to run and grow an advanced economy and to enable developing countries to boost economic output and raise living standards (IAEA, 2012). The fourth generation nuclear reactor represented by the lead-cooled fast reactor(LFR) has attracted more and more countries' attention due to its safety, miniaturization, modularity, and other advantages, and is considered a potential and feasible nuclear option to mitigate climate change (IAEA, 2020).

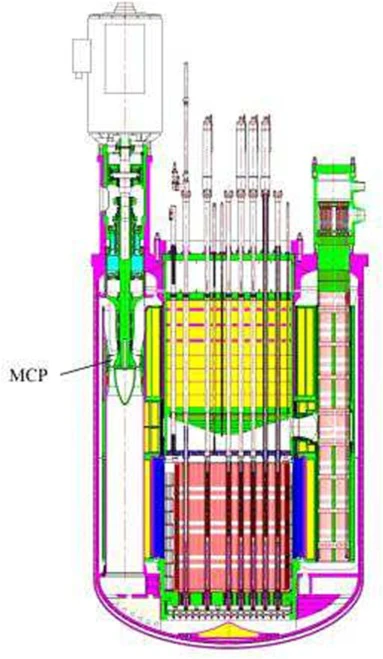

LFR has the advantages of high energy density, good intrinsic safety, and high nuclear fuel utilization efficiency (Alemberti, 2016, Alemberti et al., 2014, Lorusso et al., 2018). It has been listed as the most promising fourth-generation reactor type for commercial applications by the International Forum on the Fourth Generation Nuclear Energy System and is also one of the hot nuclear technologies in the nuclear energy field in the recent 20 years (Gong et al., 2022, Lorusso et al., 2018). As the heart of the nuclear island, the main coolant pump (MCP) plays an important role in the safe and stable operation of the reactor. Therefore, the MCP is also an important part of LFR research.

Ferrini et al. (Ferrini et al., 2016) conducted sufficient theoretical analysis and numerical simulation verification on the multi-blade screw pump as the MCP of LFR and demonstrated its feasibility as the MCP of LFR. Based on the in-depth analysis of the structural characteristics of various types of LFR, the layout of reactor components and the design scheme of the primary cooling circulating system, Yonggang Lu (Lu, 2019, Lu et al., 2021, Lu et al., 2022, Lu et al., 2019) obtained, and clarified the selection principle for the MCP of the LFR, according to the specific design parameters, and conducted in-depth research on the flow characteristics of the lead cooled fast reactor main circulating pump under different working conditions. Wang Kailin et al. (Wang, 2020, Wang et al., 2019, Wang et al., 2020, Wang et al., 2021) used numerical simulation methods to carry out the design research and hydraulic performance analysis of the axial flow MCP of LFR with the goal of reducing the relative speed in the pump. Yan Wang et al. (Wang et al., 2020b, Wang, 2020) studied the hydraulic performance and pressure fluctuation characteristics in the axial flow MCP of LFR. Shuanglei Zhang et al. (Zhang et al., 2022) optimized the outlet of the impeller and the thickness of the guide vane of the axial flow MCP in LFR, which improved the flow field structure at the outlet of the impeller effectively and reduced the velocity at the guide vane outlet.

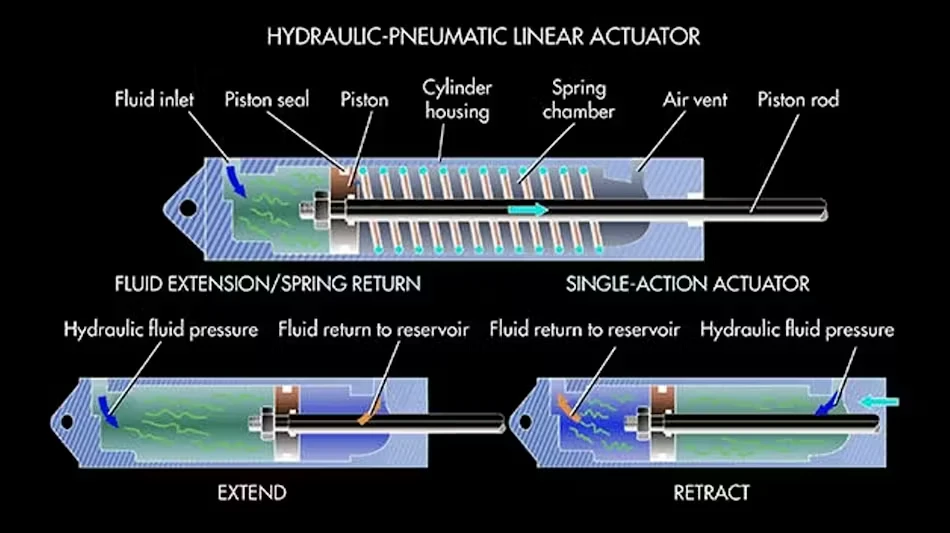

All above, scholars focus on research such as the pump type selection, the structure design, and the velocity control of the MCP in LFR. LFR uses liquid heavy metal (LHM), lead, or lead–bismuth eutectic alloy (LBE) as the coolant, which has completely different physical parameters from the traditional nuclear reactor coolant, water. Different physical parameters will lead to obvious differences in the flow state of coolant in the reactor system. Especially the MCP, as the heart of the entire nuclear island, its hydraulic performance such as efficiency and head will be affected by that. LHM, lead or LBE, has a strong natural circulation ability, and the flow resistance of the reactor system is small, so the MCP of LFR is mainly a low-head pump. At present, most LFRs basically use the axial flow pump as the MCP (Borreani et al., 2017, Iaea, 2020) as shown in Fig. 1. The hydraulic performance of the axial flow pump is affected obviously by physical parameters such as the density and viscosity of the working medium. Because of the particularity of the working environment of the MCP, the hydraulic performance of the MCP is generally tested with normal-temperature water by the model pump, and then the hydraulic performance of the prototype pump is obtained through the conversion formula. At present, there is no research on the conversion relationship of the hydraulic performance for the axial flow pump under the two mediums, normal temperature water, and lead/LBE. Therefore, it is particularly necessary to carry out research on the hydraulic performance of the axial flow MCP in LFR to obtain the difference and mechanism of the hydraulic performance under water and LHM, lead, or LBE, so as to provide some reference for the hydraulic design of the MCP in LFR.

In this study, based on the SST k-w turbulence model, an axial flow pump model was simulated at multiple working conditions, and the differences of its hydraulic performance under LBE and water and the reasons were analyzed in detail, which could provide some reference for the design of the axial flow MCP in LFR.

2. Material and method

2.1. Physical parameters of LBE

LBE is composed of 44.5% lead and 55.5% bismuth by weight. It belongs to low melting point and high boiling point alloy. The melting point temperature is about 125.6 ℃ under normal pressure. Its boiling point temperature can reach 1670 ℃ (Sobolev, 2007), and it has good thermal expansion, so it can be used in natural circulation reactor. Its physical properties change with temperature as follows.

Kirillov et al. (Kirillov, 2008)obtained the following relationship between density and temperature by fitting the test data of LBE physical parameters:

pLEB = 1113.6 - 1.34. T (1) where, is the density of LBE, kg/m3; T is the Kelvin temperature, K.

American Argonne National Laboratory measured that the dynamic viscosity of molten LBE changes with temperature as follows (Martinelli et al., 2008):

uLBE = 4.94 x 10 -4 exp( 760.1/ T ) (2) is the dynamic viscosity of LBE.

Both the density and dynamic viscosity of LBE are functions of temperature. Both of them are constant at a specific temperature. Therefore, LBE can be regarded as the Newtonian fluid. In this study, the average working temperature, 400℃, of 100 MW SVBR-100 LBE (IAEA, 2020) in the Russian Federation is used as the calculated temperature. The physical parameters of LBE at 400℃ and water at normal temperature are shown in Table 1.

Table 1. Physical parameters of LBE and water.

| Medium | LBE | Water |

|---|---|---|

| Temperature/(。C) | 400 | 20 |

| Density(kg/m3) | 10,212 | 997 |

| Dynamic viscosity(Pa.s) | 0.001528 | 0.0008899 |