The Complicated World of SAE Standards

Hydraulic hose construction and performance is covered by various national and international standards including ISO, BSI, SAE, DIN, API and CETOP. Most proprietary hoses conform to one standard or another, the SAE standards being the most widely followed. SAE standards provides general, dimensional and performance specifications for the most common hoses used in hydraulic systems on mobile and stationary equipment.

SAE is based on construction technique and material of hydraulic hose. The various application parameters required when selecting hose are size, temperature, fluid type and pressure, to name a few. Depending on these criteria, the choice of hose construction will change to suit the conditions. The majority of hydraulic machines are not exotic, and typically your standard 100R1 or 100R2 ("1-wire" and "2-wire" respectively) hoses are appropriate. When extreme pressures and exotic fluids come into play, however, the options for suitable hose are reduced.

Each of the hydraulic hose styles below must meet a set of dimensional and performance characteristics as set forth by SAE, and they are designated as 100R1 through 100R19. However, SAE issues no approval source lists, certification, or letters of approval-conformance to these standards by manufacturers is strictly voluntary. In short, the standards only assure a similarity of products among different manufacturers.

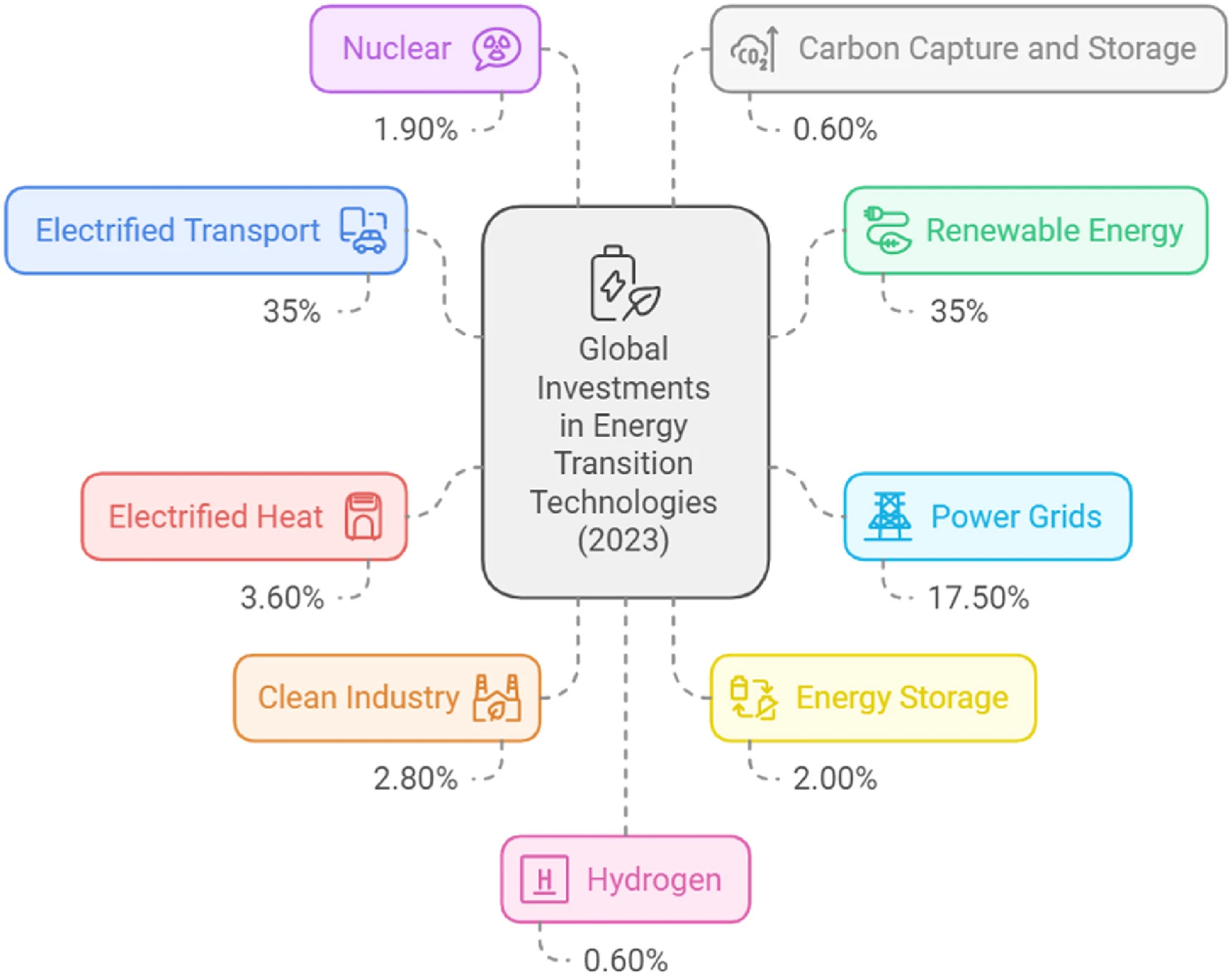

| SAE standard hydraulic hose type / application | |||||||

| Standard | Hydraulic | Temperature Range | Diameter Range | Max. Operating | Proof pressure | Min. burst Rressure | Min. bend radius |

| SAE | Fluids | ⁰F | I.D. in | Range (psi) | in | ||

| 100R1 Steel wire reinforced, rubber coated | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 2 | 575 to 3,250 | 1150 to 6,500 | 2,300 to 13,000 | 3.5 to 25 | |

| 100R2 High pressure steel wire, reinforced rubber cover – Hydraulic | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 2 | 1,150 to 6,000 | 2250 to 12,000 | 4,500 to 24,000 | 3.5 to 25 | |

| 100R3 Double fiber, braid rubber cover – High temp, low pressure hydraulic | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 1-1/4 | 375 to 1,500 | 750 to 3,000 | 1,500 to 6,000 | 3 to 10 | |

| 100R4 Wire inserted, hydraulic suction and return | |||||||

| Petroleum & water based | -40 to +212 | 3/4 to 4 | 35 to 300 | 70 to 600 | 140 to 1,200 | 5 to 24 | |

| 100R5 Single wire braid, textile cover – Transportation/DOT hose | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 3-1/16 | 200 to 3,000 | 400 to 6,000 | 800 to 12,000 | 3 to 33 | |

| 100R6 Single fiber braid, rubber cover – Transportation | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 3/4 | 300 to 500 | 600 to 1,000 | 1,200 to 2,000 | 2 to 6 | |

| 100R7 Single fiber braid, thermoplastic – Hydraulic | |||||||

| Petroleum, water based & synthetic | -40 to +212 | 1/8 to 1 | 1,000 to 3,000 | 2,000 to 6,000 | 4,000 to 12,000 | 1 to 12 | |

| 100R8 High pressure, thermoplastic - Hydraulic | |||||||

| Petroleum, water based & synthetic | -40 to +212 | 1/8 to 1 | 2,000 to 6,000 | 4,000 to 12,000 | 8,000 to 24,000 | 1 to 12 | |

| 100R9: This hose has been removed from the SAE standard. | |||||||

| 100R10: This hose has been removed from the SAE standard. | |||||||

| 100R11: This hose has been removed from the SAE standard. | |||||||

| 100R12 Heavy duty, high impulse, four-spiral wire reinforced, rubber cover – Hydraulic | |||||||

| Petroleum & water based | -40 to +250 | 3/8 to 2 | 2,500 to 4,000 | 5,000 to 8,000 | 10,000 to 16,000 | 5 to 25 | |

| 100R13 Heavy duty, high impulse, four- & six-spiral steel wire reinforced, rubber cover – Hydraulic | |||||||

| Petroleum & water based | -40 to +250 | 3/4 to 2 | 5,000 | 10,000 | 20,000 | 9.5 to 25 | |

| 100R14 High temperature, corrosive fluids, Polytetrafluorethylene (PTFE)-lined hydraulic hose, single-stainless steel braid | |||||||

| Petroleum, water based & synthetic | -65 to +400 | 3/16 to 1-1/4 | 600 to 1,500 | 1,200 to 6,000 | 2,500 to 12,000 | 1.5 to 16 | |

| 100R15 Heavy duty, ultra-high pressure, six-spiral steel wire reinforced, rubber cover – Hydraulic | |||||||

| Petroleum based | -40 to +250 | 3/8 to 1-1/2 | 6,000 | 12,000 | 24,000 | 6 to 21 | |

| 100R16 Compact, high pressure, two-braided wire reinforced rubber cover – Hydraulic hose cover | |||||||

| Petroleum & water based | -40 to +212 | 1/4 to 1-1/4 | 1,800 to 5,800 | 3,600 to 11,600 | 7,200 to 23,200 | 2 to 8 | |

| 100R17 Compact, maximum operating pressure, one- and two-steel braided wire reinforced rubber cover – Hydraulic | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 1 | 3,000 | 6,000 | 12,000 | 2 to 6 | |

| 100R18 Thermoplastic, synthetic-fiber reinforcement, and a hydraulic fluid & weather-resistant thermoplastic cover – Hydraulic | |||||||

| Petroleum, water-based, synthetic | -40 to +212 | 1/8 to 1 | 3,000 | 6,000 | 12,000 | 1 to 10 | |

| 100R19 Compact, maximum operating pressure, one- and two-braided steel wire, reinforced rubber cover – Hydraulic | |||||||

| Petroleum & water based | -40 to +212 | 3/16 to 1 | 4,000 | 8,000 | 16,000 | 2 to 6 | |

Raise your expectations and think beyond SAE standards

When comparing hose manufacturers, you need to consider products that exceed the SAE minimum performance but also meet or exceed additional certifications such as ISO to maximize performance, hose life, and production costs. Parker Hose Products Division has a full line of hydraulic hoses designed for one-half SAE bend radius at full SAE pressure, which exceeds the minimum bend radius. For example, the bend radius of Parker’s 797 hydraulic hose is half of SAE’s 100R1, 100R2, 100R4, 100R12 and 100R13 minimum requirement, which reduces hose length requirements by up to 47%. The tighter bend radius means fewer bent tube fittings and longer life in applications where machinery movement causes hoses to bend sharply. It also means reduced inventory requirements. Another example of exceeding SAE standards is Parker’s 787 hose that has nearly 30% smaller O.D. by area than SAE spiral. The compact design reduces the weight of the hose as well as footprint.

For lower pressure applications, consider Parker's 387 (3,000 psi), 487 (4,000) and 722 (4,000 psi) hoses that exceed performance requirements of both SAE and ISO.

Not sure what the difference is between SAE and ISO standards?