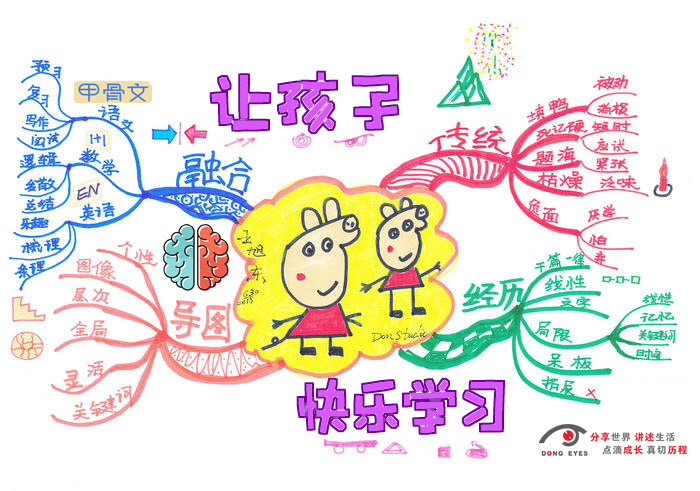

MindMap | 让孩子快乐学习之启蒙篇

让孩子快乐学习,让我们爱上学习,丽芳老师在课程中讲述了传统的学习方法的一些不足,传统的学习方式是受到历史、环境、国家等因素的限制,在当时也许是促进了教育或者国民素质的提高。

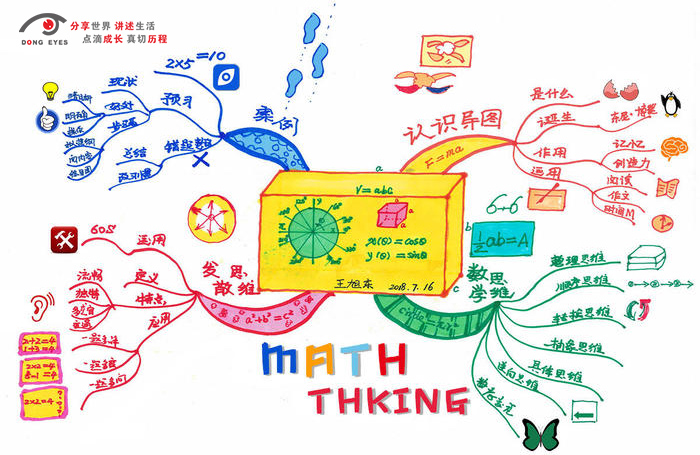

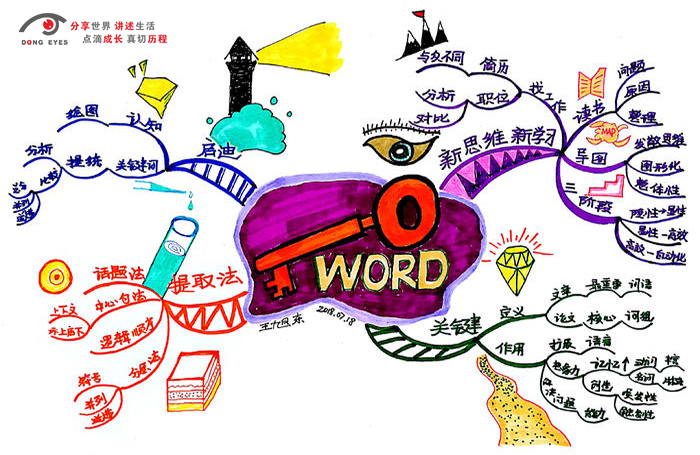

但现在科技发展至今、我们对人类的认知科学、脑科学、教育学、心理学等都有更深层次的认识,了解到了思维导图是一个非常好的工具,可以对传统的思维进行有效的改善和补充。可以让孩子的、成人的学习有了更好的工具,可以更快乐的学习。

学习类型的分类有很多,丽芳老师给我讲述了,VARK-视觉,听觉,读写和动觉学习者。每个人或者学习者只有从自身的学习类型出发,教师教学从教育者的角度发现被教育者的学习类型,结合相应的特点给予授课和讲授,个性化的教育将会让更多的学习者受益。视觉型的学习者,结合思维导图,全脑思维将学习变得更快乐!工具还要结合学科教育,丽芳老师给我们举了很多与学科结合的案例,我们小伙伴结合自身的加以学习和应用。让更多的孩子快乐学习吧!