MindMap | Keywords

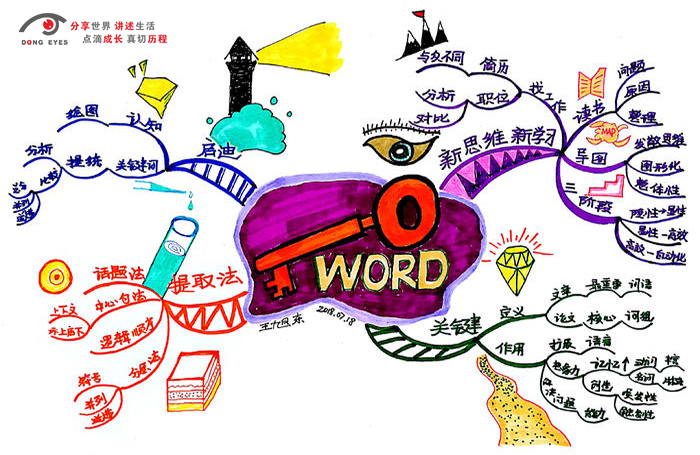

MindMap KeyWord 思维导图关键词之道从四个方面来讲述:新的思维和学习模式,关键词的概念,关键词提取法,关键词的启迪。

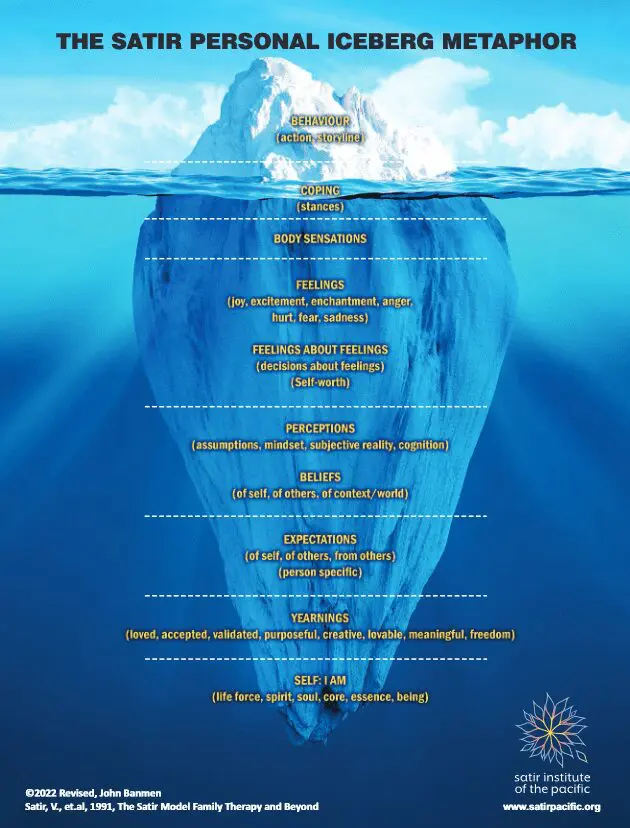

新的思维和学习模式

丽芳老师给我们讲述了关于如何在找工作中找到令人耳目一新的简历,如何对比分析职位的要求与个人技能,如何更好的阅读和读书,思维导图提供的新思维和学习模式:可以提供很好的发散思维模式,图形化,整体性思维和学习。学习的三个阶段,从隐形到显性,从显性到高效,从高效到自动化。

思维和学习模式

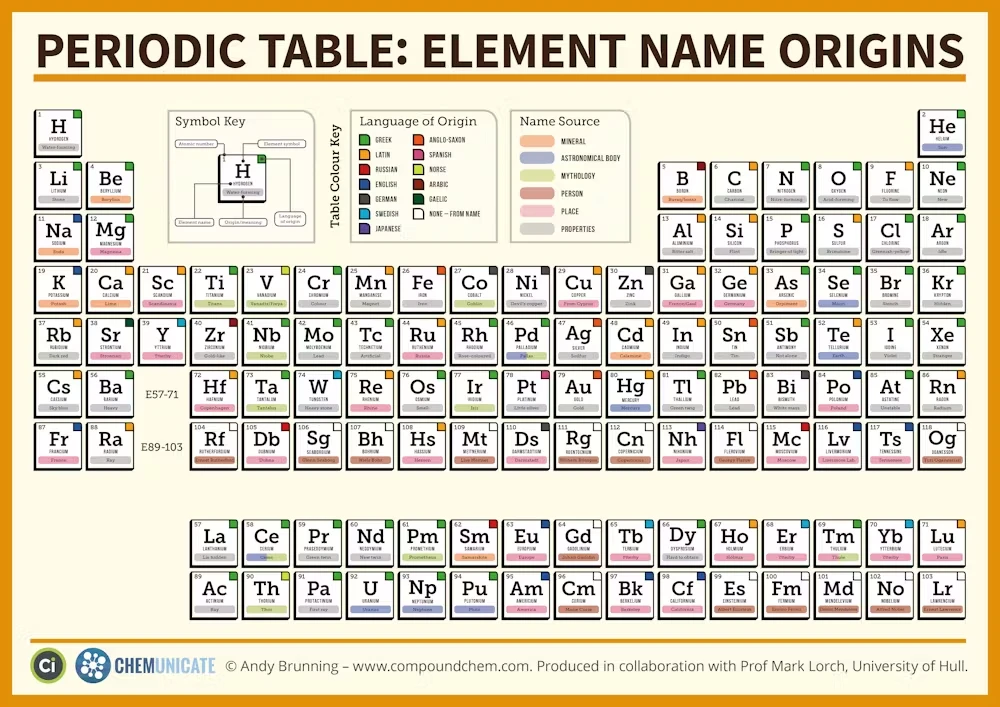

关键词

关键词的定义,关键词源于英文“keywords”,特指单个媒体在制作使用索引时,所用到的词汇。是图书馆学中的词汇。关键词搜索是网络搜索索引主要方法之一,就是访问者希望了解的产品、服务和公司等的具体名称用语。

关键词之法

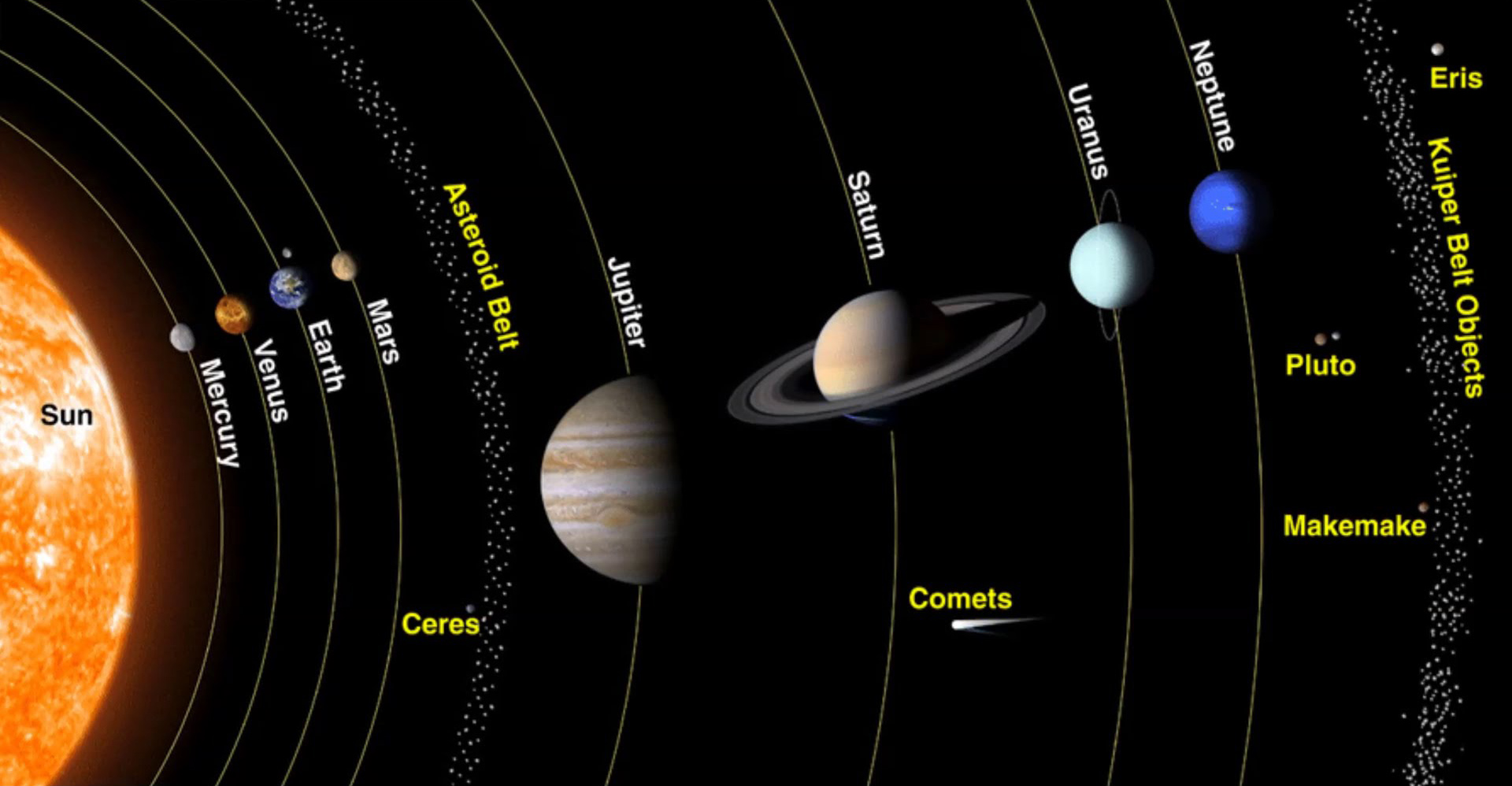

关键提取法

关键次提取的四种方法:话题法,中心句法,逻辑顺序法,分层法。

关键词选取

启迪与智慧

关键词的提取智慧,无论是直接从题目中抽取的名词和动词,还是从小标题、正文或摘要里抽取的部分词汇,要适“度”,都必须标注单一的概念,切忌复合概念。

启迪的智慧