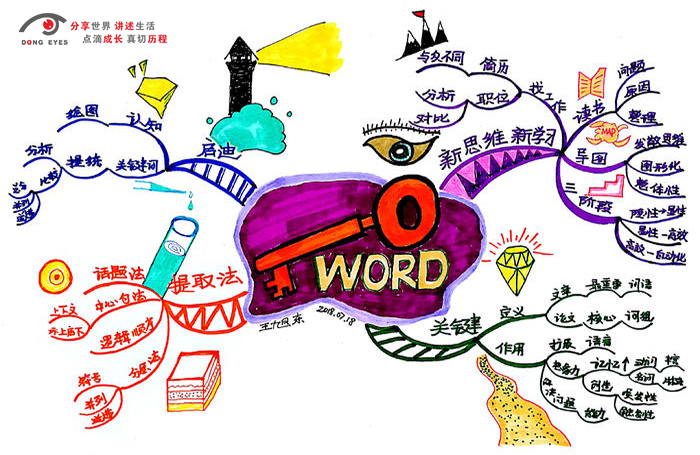

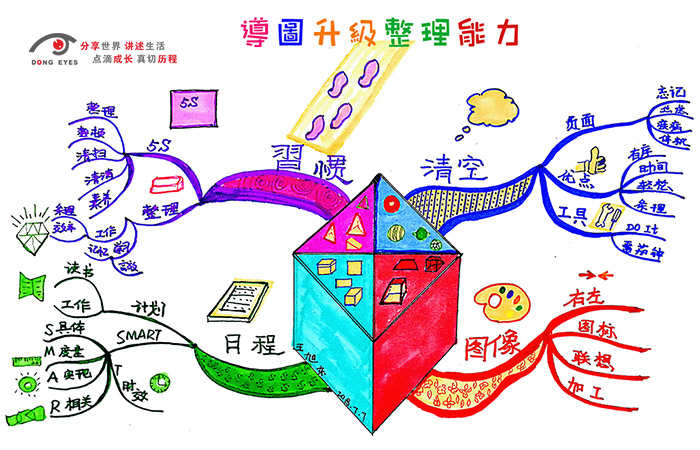

MindMap | Constructing a Knowledge System

思维导图 | 建构知识体系

学习的定义

“学习”是指通过获取经验或知识,从而改变行为或思维模式的过程。这个过程可以是自觉的,也可以是不自觉的,可以是主动的,也可以是被动的。学习是一个复杂而多层次的过程,学习的具体形式和方式因人而异,涉及到信息获取、理解、应用和反思新知识和技能。它不仅仅是在学校里进行的,而是在我们的整个生活中都在进行的一种活动。

学习,是指通过阅读、听讲、思考、研究、实践等途径获得知识或技能的过程。学习分为狭义与广义两种:

学习狭义定义

通过阅读、听讲、研究、观察、理解、探索、实验、实践等手段获得知识或技能的过程,是一种使个体可以得到持续变化(知识和技能,方法与过程,情感与价值的改善和升华)的行为方式。例如通过学校教育获得知识的过程。

学习广义定义

是人在生活过程中,通过获得经验而产生的行为或行为潜能的相对持久的行为方式。

建构主义

建构主义的最早提出者可追溯至瑞士的皮亚杰(Jean Piaget)。他是认知发展领域最有影响的一位心理学家,他所创立的关于儿童认知发展的学派被人们称为日内瓦学派。皮亚杰的理论充满唯物辩证法,坚持从内因和外因相互作用的观点来研究儿童的认知发展。

他认为,儿童是在与周围环境相互作用的过程中,逐步建构起关于外部世界的知识,从而使自身认知结构得到发展建构主义是一种关于知识和学习的理论,强调学习者的主动性,认为学习是学习者基于原有的知识经验生成意义、建构理解的过程,而这一过程常常是在社会文化互动中完成的。建构主义的提出有着深刻的思想渊源,它具有迥异于传统的学习理论和教学思想,对教学设计具有重要指导价值。

皮亚杰 建构理论

神奇的大脑

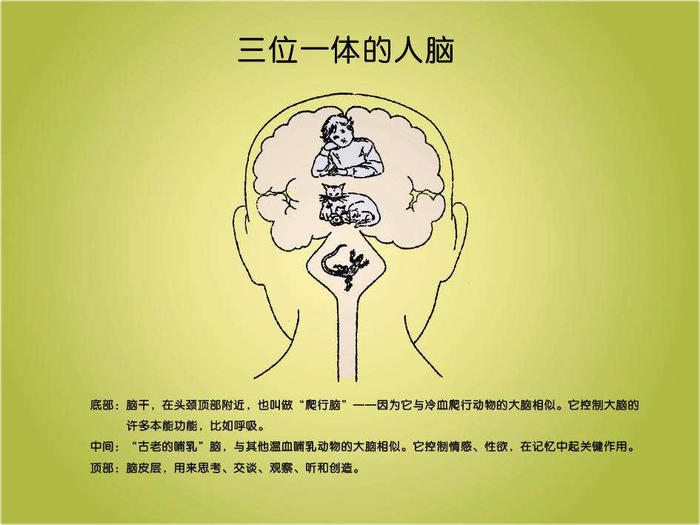

三位一体的大脑

爬行动物脑

“爬行动物脑”是最先出现的脑结构,这第一阶段大脑的演化,发生在2.5亿年前,我们称其为“旧脑”、“爬虫脑”或“鳄鱼脑”。爬虫脑演化是为了生存,其控制生命基本功能,如心跳、呼吸、打架、逃命、喂食和繁殖等功能。这一层大脑,它们没有情绪,没有理智,只有 5 种应激反应,都可以用 F 开头的单词描述:

1. 如果入侵者是同类,同性,且并不比自己更强壮,那么,Fight!2. 如果入侵者是同类,同性,且比自己更强壮,那么,Flee!3. 如果入侵者是同类,异性,那么,Fuck!4. 如果入侵者不是同类,管它是同性还是异性,只要不比自己更强壮,那么,Feed!5. 如果以上皆不是,那么,Freeze……

古哺乳动物脑

“古哺乳动物脑”,即边缘系统(limbic system),又被称为“哺乳脑”、“情绪脑”、“间脑”,人体的哺乳脑,和所有哺乳类的大脑,在本质上并无二致,包含感觉和情绪,拥有玩乐的欲望,也是母性的来源。这一层大脑用来生成各种情绪,包括最基本的恐惧、兴奋等等,这样的情绪,实际上是对各种外部刺激的高级综合反应,感受到危险要产生恐惧,以便迅速逃离;见到猎物要足够兴奋,以便身体各个部分协调起来足够有效率……

值得一提的是,家里的宠物(比如猫猫狗狗)虽然没有理性,但有情绪,它们也会开心,也会难过,也会兴奋,也会害怕……

新哺乳动物脑

“新哺乳动物脑”又称新皮层(Neocortex)、“新脑”、“理性脑”、“皮质脑”,人类大脑中,新皮层占据了整个脑容量的三分之二,分为左右两个半球,就是为人们所熟知的左右脑(了解更多参考:关于大脑的半球的知识清单)。

特别重要的是其中的额叶前端,它是我们大脑中的“总司令”,不但控制着我们一系列的高级认知功能,还能抑制一些低级中枢(比如,“爬行动物脑”)的活动,防止我们做出一些不恰当的行为。不夸张地讲,一切的人类文明,都建立在前脑额叶之上或者之中。

升级我们的大脑

左右脑的思考通路的不同,结合左右脑的不同特点,升级我们的大脑,让我们拥有更快的阅读,学习和工作效率。